Products

View more-

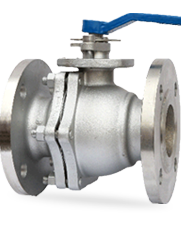

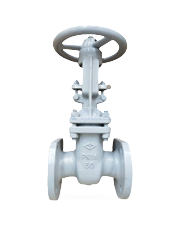

valve

Valve is a type of pipeline accessory.

It is used to open and close pipelines, control flow direction, regulate and control the conveying medium.

-

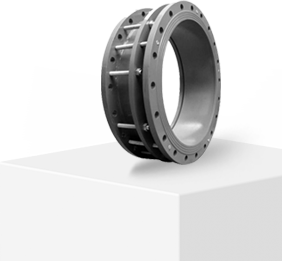

pipe fitting

Pipe fittings are a collective term for the components in a piping system. It serves as a connection, control, directional change, diversion, sealing, support, and other functions.

-

ACTUATOR

The safety and reliability of electric valves depend on the electric actuator. Therefore, the performance and control level of electric actuators are comprehensive manifestations of the overall technical level of electric valves.

About us

VIEW MOREAnhui Tsunny valve Industry Co.,Ltd is mainly responsible for international trade business, located in Anhui province which near Shanghai Port and Ningbo Port.There is the University of Science and Technology of China, which has a rich reserve of high-tech talents. Our factory was founded in 1994 and located in the hinterland of the economic circle around Beijing Tianjin and Bohai Sea.It covers an area of about 700000 m2 and has more than 4000 employees. Our products involve ANSI/API.DIN.JIS/KS.BS.NF.RUSSIA standards. The main materials include gray iron, ductile iron, WCA, WCB, WCC, LC1, LCC, CF3. CF8, WC6, WC9, C5, C12.The main products are gate valves, globe valves, check valves, butterfly valves, ball valves, as well as pipe fittings and joints. Tsunny valves focus on valves design and production.The manufacturing system and products have passed certifications such as ISO9001,ISO14001,ISO18001, Q/GDZR010 2019 5A, ANSI/API STD607, Special Equipment Test, FM, UL, JIS, etc. These have created favorable conditions for us to provide high-quality products to global customers at competitive prices.

-

700000㎡

Floor Area

-

4000+

Employees

-

200+

Product Series

-

40+

Country Of Cooperation

Applications

View more-

01

Natural Gas Heating Industry

Used in transmission lines designed according to ASME B31.4, ASME B31.8 or other equivalent standards.

Line valves are designed to API 6D and IS0 14313 standards for use in transfer lines designed to ASME B31.4, ASME B31.8 or other equivalent standards. Produce a variety of pipeline valves that can reduce pipeline pressure loss to a minimum, such as fixed ball valves, flat gate valves, fully open check valves, etc.

VIEW MORE -

02

Metallurgy and Mining Industry

The mining industry includes mining and metallurgy, and there is a large demand for wide doors in the process of beneficiation and smelting.

The mining industry includes mining and metallurgy (mineral processing + smelting), and there is a large demand for valves in the process of mineral processing and smelting. The medium usually has the characteristics of large particles, high hardness, high viscosity, or strong acid and strong alkali. It also has relatively strict requirements on the valve. In different working conditions, the valve is required to have corresponding wear resistance, magic corrosion resistance, high Liquidity equivalence point.

VIEW MORE -

03

Water Treatment Industry

The urban water supply and drainage pipe network is a bridge connecting water supply and drainage enterprises, users, and water treatment centers, which is closely related to industrial production and the life of urban residents.

The water supply and drainage pipe network is composed of various pipe accessories and fittings such as pipes and valves. In the daily water supply pipe network, water supply, water pressure scheduling and deployment, water stop for maintenance and repair, connection of new and old pipelines, pipeline flushing, etc., The valve must be opened and closed. The life and quality of the water supply and drainage valve products play a vital role in the normal operation of the water supply network.

VIEW MORE -

04

Petrochemical Industry

Oil & Gas is the main raw material for the petrochemical industry.

Refineries use thermal cracking to process crude oil and produce liquid fuels of different densities, properties and functions. Refining and chemical residues will also be reprocessed according to their type, actual needs and local regulations. The petrochemical industry filters and processes oil and natural gas to reduce its corrosion and impurities, and produces through complex and professional treatment. Required chemicals and synthetic materials.

VIEW MORE

News

View more-

Common issues and their solutions of swing check valves (e.g., leakage, clogging, improper closing)

2025.04.10

Swing check valves play a crucial role in controlling the unidirectional flow of fluid in pipeline systems and are widely used across various industries. However, over time, these valves may experience issues such as leakage, blockages, improper closing, and more, which can affect the efficiency and safety of the system. Understanding these common faults and their solutions can help users better maintain the equipment, extend its service life, and ensure the normal operation of the pipeline s... -

What Is The Difference Between Cast Iron Valves And Ductile Iron Valves

2025.03.28

In pipeline systems, valves are essential devices for controlling fluid flow, pressure, temperature, and other important parameters. The choice of valve material directly impacts the system's stability and service life. Common valve materials include gray cast iron and ductile cast iron. Although both materials belong to the cast iron category, they differ significantly in performance, applicable environments, and areas of use. This article will provide a detailed introduction to the differen... -

Cast Iron Y-Strainers: A Cost-Effective Solution for Long-Term Pipeline Protection

2025.03.11

In pipeline systems, choosing the right filter is crucial, especially when you want to reduce maintenance costs and ensure long-term equipment performance. Cast iron Y-strainers have become a popular choice in many industrial fields due to their durability, efficiency, and cost-effectiveness. Here’s why cast iron Y-strainers are a long-term, cost-effective solution for pipeline protection. 1. Strong Durability Cast iron is known for its strength and pressure resistance, making it id... -

Why Are Explosion-Proof Pipe Joints Essential for Hazardous Environments

2025.02.26

An explosion-proof pipe joint is a specialized connecting device designed for hazardous environments. Its primary function is to ensure that the connection points of pipeline systems in flammable, explosive, or corrosive environments do not leak or cause explosions. These joints are made of high-quality carbon steel or stainless steel, offering high strength, corrosion resistance, and high-temperature resistance, making them suitable for various complex working conditions. Materials ...